- 您现在的位置:买卖IC网 > Sheet目录839 > AU016D104KAG2A (AVX Corporation)CAP CER 0.1UF 6.3V 10% 0201

�� �

�

�

�Surface� Mounting� Guide�

�MLC� Chip� Capacitors�

�COMMON� CAUSES� OF�

�MECHANICAL� CRACKING�

�The� most� common� source� for� mechanical� stress� is� board�

�depanelization� equipment,� such� as� manual� breakapart,� v-�

�cutters� and� shear� presses.� Improperly� aligned� or� dull� cutters�

�may� cause� torqueing� of� the� PCB� resulting� in� flex� stresses�

�being� transmitted� to� components� near� the� board� edge.�

�Another� common� source� of� flexural� stress� is� contact� during�

�parametric� testing� when� test� points� are� probed.� If� the� PCB�

�is� allowed� to� flex� during� the� test� cycle,� nearby� ceramic�

�capacitors� may� be� broken.�

�A� third� common� source� is� board� to� board� connections� at�

�vertical� connectors� where� cables� or� other� PCBs� are�

�connected� to� the� PCB.� If� the� board� is� not� supported� during�

�the� plug/unplug� cycle,� it� may� flex� and� cause� damage� to�

�nearby� components.�

�Special� care� should� also� be� taken� when� handling� large� (>6"�

�on� a� side)� PCBs� since� they� more� easily� flex� or� warp� than�

�smaller� boards.�

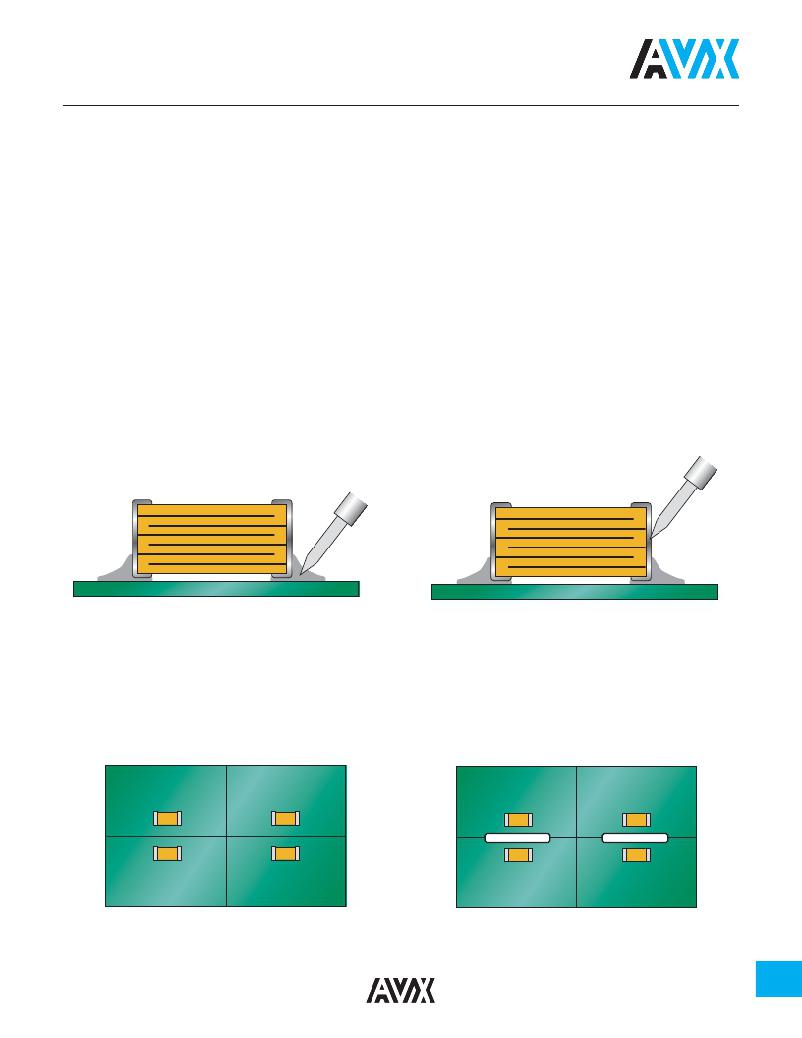

�Solder� Tip�

�Preferred� Method� -� No� Direct� Part� Contact�

�REWORKING� OF� MLCS�

�Thermal� shock� is� common� in� MLCs� that� are� manually�

�attached� or� reworked� with� a� soldering� iron.� AVX� strongly�

�recommends� that� any� reworking� of� MLCs� be� done� with� hot�

�air� reflow� rather� than� soldering� irons.� It� is� practically�

�impossible� to� cause� any� thermal� shock� in� ceramic�

�capacitors� when� using� hot� air� reflow.�

�However� direct� contact� by� the� soldering� iron� tip� often�

�causes� thermal� cracks� that� may� fail� at� a� later� date.� If� rework�

�by� soldering� iron� is� absolutely� necessary,� it� is� recommended�

�that� the� wattage� of� the� iron� be� less� than� 30� watts� and� the�

�tip� temperature� be� <300oC.� Rework� should� be� performed�

�by� applying� the� solder� iron� tip� to� the� pad� and� not� directly�

�contacting� any� part� of� the� ceramic� capacitor.�

�Solder� Tip�

�Poor� Method� -� Direct� Contact� with� Part�

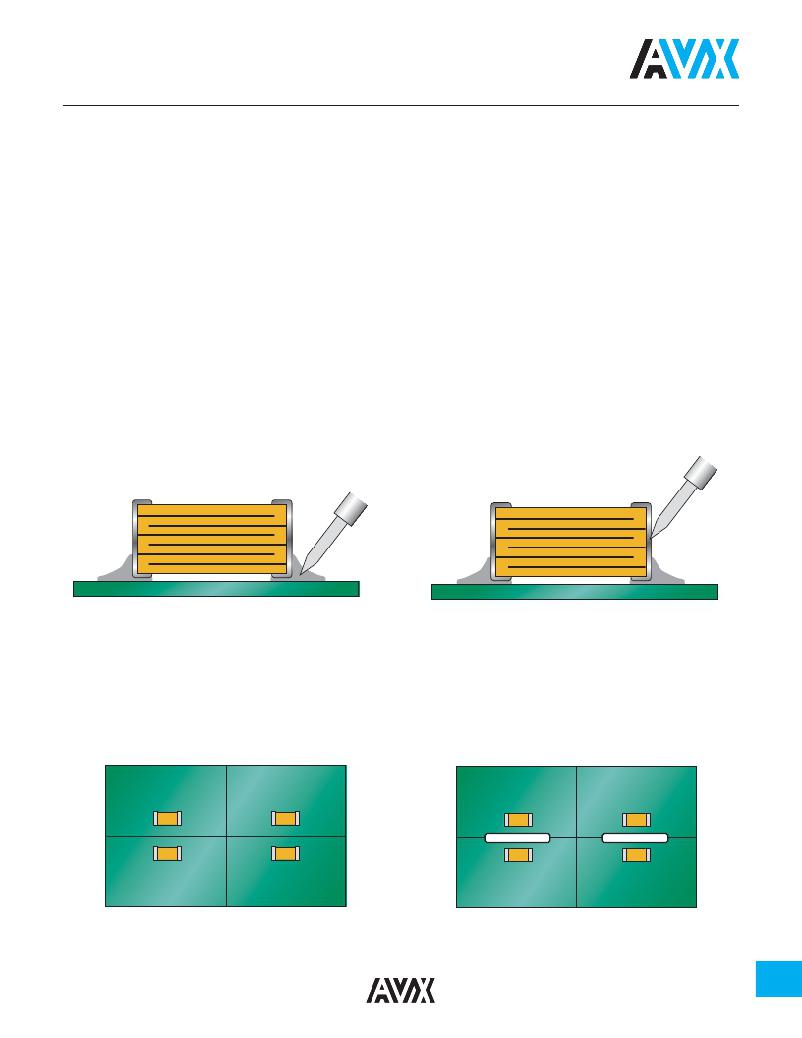

�PCB� BOARD� DESIGN�

�To� avoid� many� of� the� handling� problems,� AVX� recommends� that� MLCs� be� located� at� least� .2"� away� from� nearest� edge� of� board.�

�However� when� this� is� not� possible,� AVX� recommends� that� the� panel� be� routed� along� the� cut� line,� adjacent� to� where� the� MLC� is�

�located.�

�No� Stress� Relief� for� MLCs�

�Routed� Cut� Line� Relieves� Stress� on� MLC�

�113�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

AVE477M10G24T-F

CAP ALUM 470UF 10V 20% SMD

AVEK337M10G24T-F

CAP ALUM 330UF 10V 20% SMD

AVES226M35D16T-F

CAP ALUM 22UF 35V 20% SMD

AVEZ476M35X16T-F

CAP ALUM 47UF 35V 20% SMD

AVRF107M35F24T-F

CAP ALUM 100UF 35V 20% SMD

AVS107M50G24B-F

CAP ALUM 100UF 50V 20% SMD

B048F160T24

BCM BUS CONVERTER 16V 240W

B048F320T30

BCM BUS CONVERTER 32V 300W

相关代理商/技术参数

AU016D104KAG2A-5K

功能描述:多层陶瓷电容器MLCC - SMD/SMT 100nF 10% 6.3 Volts Gold Flash RoHS:否 制造商:American Technical Ceramics (ATC) 电容:10 pF 容差:1 % 电压额定值:250 V 温度系数/代码:C0G (NP0) 外壳代码 - in:0505 外壳代码 - mm:1414 工作温度范围:- 55 C to + 125 C 产品:Low ESR MLCCs 封装:Reel

AU016D104MAG2A

功能描述:多层陶瓷电容器MLCC - SMD/SMT 6.3volts 0.1uF 20% X5R 0201 SIZE

RoHS:否 制造商:American Technical Ceramics (ATC) 电容:10 pF 容差:1 % 电压额定值:250 V 温度系数/代码:C0G (NP0) 外壳代码 - in:0505 外壳代码 - mm:1414 工作温度范围:- 55 C to + 125 C 产品:Low ESR MLCCs 封装:Reel

AU016D223KA72A

功能描述:多层陶瓷电容器MLCC - SMD/SMT 6.3volts 0.01uF 10% X5R 0201 SIZE

RoHS:否 制造商:American Technical Ceramics (ATC) 电容:10 pF 容差:1 % 电压额定值:250 V 温度系数/代码:C0G (NP0) 外壳代码 - in:0505 外壳代码 - mm:1414 工作温度范围:- 55 C to + 125 C 产品:Low ESR MLCCs 封装:Reel

AU016D223KAG2A

功能描述:多层陶瓷电容器MLCC - SMD/SMT 6.3volts 22000pF 10% X5R

RoHS:否 制造商:American Technical Ceramics (ATC) 电容:10 pF 容差:1 % 电压额定值:250 V 温度系数/代码:C0G (NP0) 外壳代码 - in:0505 外壳代码 - mm:1414 工作温度范围:- 55 C to + 125 C 产品:Low ESR MLCCs 封装:Reel

AU01A

制造商:Sanken Electric Co Ltd 功能描述:Pack 制造商:Sanken Electric Co Ltd 功能描述:Bulk

AU01AV

制造商:Sanken Electric Co Ltd 功能描述:DIODE FAST REC AXIAL

AU01AV0

制造商:Sanken Electric Co Ltd 功能描述:DIODE FAST REC AXIAL

AU01AV1

制造商:Sanken Electric Co Ltd 功能描述:DIODE FAST REC AXIAL